Introduction

In today’s context of growing concern for biosafety, bio-decontamination has become a fundamental requirement in laboratories, hospitals, pharmaceutical industries, and research facilities. It consists of a set of processes aimed at the total or significant elimination of microbiological contaminants – namely bacteria, viruses, fungi, and spores – present on surfaces, equipment, or enclosed environments.

Effective application of bio-decontamination techniques helps prevent infections, protect experimental data, ensure the integrity of sensitive products, and comply with strict legal and regulatory requirements. We have developed innovative solutions that stand out in this field, offering advanced and sustainable systems that address the real challenges of microbiological control.

Scientific relevance of bio-decontamination today

Bio-decontamination is a critical process in biosafety, biomedical research, and pharmaceutical manufacturing, with the main goal of eliminating or inactivating biological contaminants present in controlled environments. This process goes beyond common disinfection: it requires effective elimination of resistant microorganisms such as bacterial spores, enveloped viruses, fungi, and emerging pathogens. From a regulatory standpoint, the effectiveness of bio-decontamination is often quantified by the logarithmic reduction of microbial load – with the international standard being at least a 6-log reduction (i.e., 99.9999% elimination of viable agents).

This level of demand makes bio-decontamination essential in areas such as cleanrooms, biological safety level 3/4 laboratories, sterile pharmaceutical production units, and research environments working with high-risk pathogens. Failure to fully eliminate biological agents can lead to cross-contamination, loss of sample integrity, false positives in assays, or, in more severe cases, infection outbreaks linked to environmental control failures.

Technological advances and trends in bio-decontamination

Technological evolution in the field of bio-decontamination is marked by increasing demand for methods that combine microbial efficacy, operational safety, and environmental sustainability. Traditional chemical decontamination, while effective, presents challenges such as residual toxicity, corrosiveness, and operator risks, motivating the development of innovative alternatives.

The trend also points towards portable, rapid-deployment, low-energy consumption solutions usable across sectors ranging from pharmaceutical manufacturing to healthcare services and research laboratories. In this scenario, Delox technology stands out as a paradigm of Portuguese innovation fully meeting current bio-decontamination requirements by ensuring effective, safe, and sustainable cycles.

Delox: Portuguese innovation in bio-decontamination technologies

Delox is a science-based company, a spin-off from the Faculty of Sciences of Lisbon University, dedicated to developing innovative solutions for bio-decontamination

Delox’s solid hydrogen peroxide is activated by heat (60–65 °C), releasing dry vapor that distributes evenly inside the space to be decontaminated, ensuring the elimination of microorganisms even in hard-to-reach areas. The absence of toxic residues and natural decomposition into water and oxygen make this method especially attractive from an environmental standpoint.

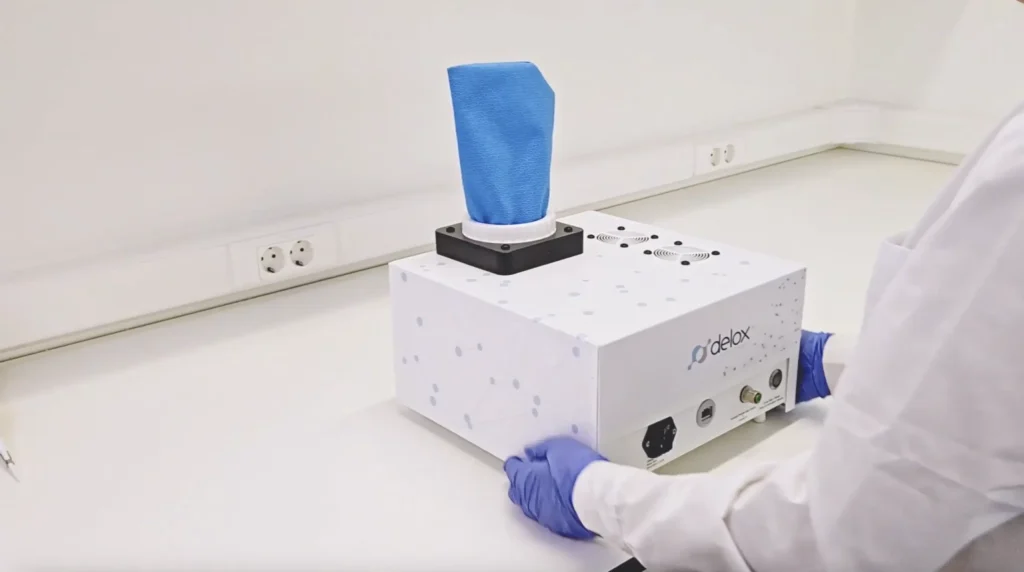

Delox Box: the portable and effective solution

The company’s main product, the Delox Box, was designed for automated decontamination of volumes up to 2 m³. With a compact, lightweight, and intuitive design, this equipment targets laboratory, clinical, industrial, and military applications, allowing validated bio-decontamination cycles with high efficacy and traceability.

Technical specifications:

- Dimensions: 22 x 29 x 22 cm

- Weight: 5.5 kg

- Set-up time: <10 minutes

- Operating temperature: 60–65 °C

- Uses DeloxHP 100 or 200 cartridges

- Digital interface

Practical applications: REUSE Project

During the COVID‑19 pandemic, Delox participated in the REUSE Project, which aimed at decontaminating and safely reusing personal protective equipment (PPE) in hospital and military environments. Collaboration with the Portuguese Army and Faculty of Sciences allowed implementation of decontamination cycles for FFP2/N95 masks and other critical materials.

The results demonstrated:

- Total elimination of microbial load

- Preservation of material properties after multiple cycles

- Safe operation in medical environments without the need for external ventilation

- Compliance with European Biosafety Association recommendations.

Comparison with traditional methods

| Method | Temperature | Residues | Operator Safety | Regulation |

| Formaldehyde | Ambient | Highly toxic | Carcinogenic | Hazardous substance |

| Ethylene oxide | Ambient | Flammable and toxic | Requires quarantine time | Hazardous substance |

| Traditional VHP | >130 °C | Water + oxygen | Hydrogen peroxide in high concentrations (35-50%, is very corrosive and flammable. | Hazardous substance |

| DeloxHp | 60 °C | Water + oxygen | Safe and non-corrosive | Not regulated as hazardous |

Safety, verifiable, and sustainability

Delox technology also stands out for:

- Operational safety: cartridges are non-flammable and non-corrosive, with no hazardous transport classification

- Easily Validated: cycles can be easily validated through the use of biological and/or chemical indicators

- Environmental sustainability: no residues, no need for chemical neutralization, low energy, breaks down to water and oxygen

- Compatibility with Delox’s Hydrogen Peroxide Sensor and optional catalyst (Delox Catalyser)

- Size: Delox’s technology simplifies hydrogen peroxide vapor generators (bio-decontamination units), making the equipment compact enough to fit inside most chambers

After each cycle, space can be immediately reused without risks to people, samples, or sensitive equipment.

Conclusion

Bio-decontamination is an indispensable requirement today in multiple sectors where microbiological safety is critical. Delox technology, particularly the Delox Box, represents an effective, scientifically validated, operator-safe, and environmentally friendly approach.

With portable solutions based on solid hydrogen peroxide, and proven real-world applications, Delox positions itself as a reference in innovation in the field of bio-decontamination.

Want to know more?

If you are looking for a safe, innovative, and sustainable solution for bio-decontamination processes, discover how Delox can help protect your laboratory, production unit, or critical facility. Contact us for a demonstration or to clarify any questions.